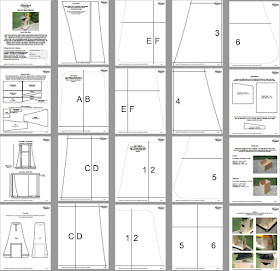

If you would like to make one of these yourself, click here to download my PDF plan. You may need to adjust the dimensions to fit your particular bowls and food container. Click here for dog bowls like the ones I used (affiliate link). Your dog is gonna love it!

Pages

▼

Tuesday, December 20, 2016

Raised Dog Food and Water Bowl Stand

This raised Dog Food and Water Bowl Stand is an easy woodworking project that you can make in one or two days. I made this from regular 3/4" lumber from the home center. Check out the video and then make one for your pet!

If you would like to make one of these yourself, click here to download my PDF plan. You may need to adjust the dimensions to fit your particular bowls and food container. Click here for dog bowls like the ones I used (affiliate link). Your dog is gonna love it!

If you would like to make one of these yourself, click here to download my PDF plan. You may need to adjust the dimensions to fit your particular bowls and food container. Click here for dog bowls like the ones I used (affiliate link). Your dog is gonna love it!

Sunday, November 27, 2016

Making a Magazine Rack

I made this Magazine Rack out of wood and clear acrylic. This is an easy woodworking project that would make a great gift for any avid reader. It only took a few hours and it's made completely from scrap materials I already had in the shop.

I enjoy going into the shop with just an idea for a project and making it up as I go. If you've ever watched the American Pickers show, you've probably seen them talk about "Freestyling" where anything goes and you just wing it. I did some freestyling to create this Magazine Rack out of leftover materials. It's going to look great in my library!

I enjoy going into the shop with just an idea for a project and making it up as I go. If you've ever watched the American Pickers show, you've probably seen them talk about "Freestyling" where anything goes and you just wing it. I did some freestyling to create this Magazine Rack out of leftover materials. It's going to look great in my library!

Sunday, November 13, 2016

Sidebar Conversation Workshop Update!

Here's a quick Sidebar Convo shop update. I haven't done one of these since June, so it's long overduc. Check out what's been going on in my shop!

Below are links to all of the stuff that I mentioned in this sidebar convo:

Below are links to all of the stuff that I mentioned in this sidebar convo:

- Makers Rock Album Art Collaboration Playlist

- Got Stickers? Email me at thecarmichaelworkshop@gmail.com to trade, or you can get one of my stickers from my Etsy Shop.

- Subscribe to Nathan's channel "A Young Man's Workshop".

- I was a guest on several episodes of the Woodshop 101 podcast.

- Ryan from the Waylight Creations channel is doing a series of Ask the Maker videos. It's cool to hear what everyone has to say about various topics. I was on the episode about Freebooting.

Sunday, October 23, 2016

Makers Rock Pink Floyd Album Cover Art and Giveaway!

I recreated the album cover for Pink Floyd's The Wall using maple and walnut for the 2016 Makers Rock Album Art Collaboration with five of my YouTube friends. Check out the video of the project below, then enter my giveaway for the album art and a DIY Speaker Kit from Rockler Woodworking and Hardware!

Here is a picture of the album art and Rocker DIY Speaker Kit bundle that will go to one winner. Enter to win in the Rafflecopter widget below. Thanks to Rockler for supporting our woodworking community and providing this awesome prize!

Giveaway is open to legal residents of the 48 contiguous United States who are age 18 or older. The deadline to enter is Friday, October 28th at 11:59PM Pacific. The winner will be selected by random drawing on Saturday, October 29th and posted here with the Rafflecopter widget below.

a Rafflecopter giveaway

Watch all of the Makers Rock Album Art projects right here in one place! Be sure to subscribe to their channels and don't forget to enter their giveaways too!

Here is a picture of the album art and Rocker DIY Speaker Kit bundle that will go to one winner. Enter to win in the Rafflecopter widget below. Thanks to Rockler for supporting our woodworking community and providing this awesome prize!

a Rafflecopter giveaway

Watch all of the Makers Rock Album Art projects right here in one place! Be sure to subscribe to their channels and don't forget to enter their giveaways too!

Saturday, October 15, 2016

Makers Rock Album Art Collaboration 2016

A group of us makers and woodworkers are remaking some of our favorite album covers! I'm making Pink Floyd's The Wall out of maple and walnut. We're also going to be giving them away! Check out this video for details about the Makers Rock Album Art Collaboration 2016, then watch for our projects on YouTube on Sunday, October 23rd!

Subscribe to all of the makers below so you don't miss any of the Makers Rock Album Art projects! Rock on!

Saturday, September 24, 2016

10 Fun Scroll Saw Woodworking Projects

I challenged myself to create an eBook of 10 Fun Scroll Saw Projects that you can cut out and assemble using interlocking joints - no glue, screws, or nails required - it's that simple! Check out my video featuring all ten projects, and if you like what you see, Click Here to purchase my eBook!

It was a fun challenge trying to design these projects with slots that just slide together to assemble the project. I have a Dewalt DW788 Scroll Saw, but you could probably make these with a jigsaw and bandsaw as well. Most of the projects can be made in less than an hour so they don't take much time. I started simple with this Phone Stand made from 1/4" plywood. It has two sides that hold your phone at different angles.

This Tablet Stand consists of only two pieces of 1/4" plywood. It is also two-sided for different angles. It will hold tablets that are 7" or larger. When making interlocking projects, it's important to measure the thickness of the wood so you know how wide to cut the slots.

I needed a Laptop Stand that I could knock down and put in a laptop bag. This is made from 1/2" plywood and is sized to hold my 17.3" laptop. It's sturdy and has lots of ventilation. This project can be customized to fit other size laptops.

This Desk Clock made from 1/2" plywood would look great on any desk or mantle. It uses a 2-3/4" Clock Shoppe Insert. I really like the simplicity and art deco style of this design. I suggest buying the clock part before cutting the hole so you can measure for a perfect fit.

The 14-inch Basket is made from 1/4" plywood and would look great as a table centerpiece. You could also turn it upside down to use as a display stand. This project can be glued together, as it may come apart easily depending on what you put in it.

Who doesn't need a drink tote for a 6-pack of soda or beer? This project is made from both 1/4" and 1/2" plywood. I suggest painting or finishing this one since it may get wet. This would make a great gift with someone's favorite drink. Speaking of which, I need to put something in mine.

This Flashlight Lamp is made from 1/4" plywood and uses a Harbor Freight Flashlight as its light source. Any flashlight with a 1" diameter should fit. This design lends itself well for displaying something on the bottom shelf.

If you are old like me, you might remember playing with balsa wood airplane kits. This Biplane will take you back to your childhood. The fuselage is cut from 1/2" plywood, and the rest of the parts are 1/4" plywood. It doesn't fly very well, but it looks pretty cool. Hang it from the ceiling with some string!

A woodworking eBook wouldn't be complete without a shop project. Make a pair of these Benchtop Sawhorses from 1/2" plywood. They are great for raising projects off the workbench for clamping or finishing. Take them apart and store them away when not in use.

This Hammerhead Shark is 3 feet long and was lots of fun to make and see it come together. It's made from a pine 1x12, which is .75" thick. I wanted to do a large animal project, so this is what I came up with. Since sharks don't have legs, I made a couple of stands to hold it up. I think it turned out pretty awesome!

Thanks for checking out my video and pictures of these projects. If you have a scroll saw, I hope these projects inspire you to dust it off and make some stuff. If you need help getting started, here is a link to my 10 Fun Scroll Saw Projects eBook. Contact me if you have any questions about these projects or how to build them.

It was a fun challenge trying to design these projects with slots that just slide together to assemble the project. I have a Dewalt DW788 Scroll Saw, but you could probably make these with a jigsaw and bandsaw as well. Most of the projects can be made in less than an hour so they don't take much time. I started simple with this Phone Stand made from 1/4" plywood. It has two sides that hold your phone at different angles.

This Tablet Stand consists of only two pieces of 1/4" plywood. It is also two-sided for different angles. It will hold tablets that are 7" or larger. When making interlocking projects, it's important to measure the thickness of the wood so you know how wide to cut the slots.

I needed a Laptop Stand that I could knock down and put in a laptop bag. This is made from 1/2" plywood and is sized to hold my 17.3" laptop. It's sturdy and has lots of ventilation. This project can be customized to fit other size laptops.

This Desk Clock made from 1/2" plywood would look great on any desk or mantle. It uses a 2-3/4" Clock Shoppe Insert. I really like the simplicity and art deco style of this design. I suggest buying the clock part before cutting the hole so you can measure for a perfect fit.

The 14-inch Basket is made from 1/4" plywood and would look great as a table centerpiece. You could also turn it upside down to use as a display stand. This project can be glued together, as it may come apart easily depending on what you put in it.

Who doesn't need a drink tote for a 6-pack of soda or beer? This project is made from both 1/4" and 1/2" plywood. I suggest painting or finishing this one since it may get wet. This would make a great gift with someone's favorite drink. Speaking of which, I need to put something in mine.

This Flashlight Lamp is made from 1/4" plywood and uses a Harbor Freight Flashlight as its light source. Any flashlight with a 1" diameter should fit. This design lends itself well for displaying something on the bottom shelf.

If you are old like me, you might remember playing with balsa wood airplane kits. This Biplane will take you back to your childhood. The fuselage is cut from 1/2" plywood, and the rest of the parts are 1/4" plywood. It doesn't fly very well, but it looks pretty cool. Hang it from the ceiling with some string!

A woodworking eBook wouldn't be complete without a shop project. Make a pair of these Benchtop Sawhorses from 1/2" plywood. They are great for raising projects off the workbench for clamping or finishing. Take them apart and store them away when not in use.

This Hammerhead Shark is 3 feet long and was lots of fun to make and see it come together. It's made from a pine 1x12, which is .75" thick. I wanted to do a large animal project, so this is what I came up with. Since sharks don't have legs, I made a couple of stands to hold it up. I think it turned out pretty awesome!

Thanks for checking out my video and pictures of these projects. If you have a scroll saw, I hope these projects inspire you to dust it off and make some stuff. If you need help getting started, here is a link to my 10 Fun Scroll Saw Projects eBook. Contact me if you have any questions about these projects or how to build them.

Monday, August 8, 2016

British Phone Booth Lamp and Charger - 2x4 Woodworking Project

This project goes out to all of my UK friends and relatives! I made a British Phone Booth Lamp and Phone Charger out of a single 8-foot 2x4 for a woodworking contest. Check out the video below!

I made this project for our local Gwinnett Woodworkers Association's 2x4 contest. There were lots of great entries this year. I got 3rd place and won a gift card for Peachtree Woodworking Supply. Below is a picture of the entries. The amazing segmented Lighthouse woodturning won 1st place, and the folding TV Table won 2nd place! It was great to see everyone up their game this year!!!

This phone booth will be easy to make if you are not limited to using a 2x4. It's basically just a box with windows and a door cut out of it. A scroll saw is a must for this project, but you could also make it with a CNC machine. Click here to download my PDF cutting templates.

The LED lights (affiliate link) really make the phone booth look awesome. My initial idea was to make it just a lamp. The phone charging station was kind of an afterthought, but it makes sense considering it does say "Telephone" on it. You should try to make something out of a single 2x4 sometime...it's a fun challenge!

I made this project for our local Gwinnett Woodworkers Association's 2x4 contest. There were lots of great entries this year. I got 3rd place and won a gift card for Peachtree Woodworking Supply. Below is a picture of the entries. The amazing segmented Lighthouse woodturning won 1st place, and the folding TV Table won 2nd place! It was great to see everyone up their game this year!!!

This phone booth will be easy to make if you are not limited to using a 2x4. It's basically just a box with windows and a door cut out of it. A scroll saw is a must for this project, but you could also make it with a CNC machine. Click here to download my PDF cutting templates.

The LED lights (affiliate link) really make the phone booth look awesome. My initial idea was to make it just a lamp. The phone charging station was kind of an afterthought, but it makes sense considering it does say "Telephone" on it. You should try to make something out of a single 2x4 sometime...it's a fun challenge!

Monday, July 25, 2016

Twine Picture Frame and Coat Rack Combo

I combined two woodworking projects into one with this Twine Picture Frame & Coat Rack combo. I made it out of scrap wood that was left over from my previous Sliding Barn Door and Easy Wall Shelves projects. Check out the video below.

I made this project for my daughter's room, so I took the opportunity to add some pictures of inspirational ladies in the DIY/Woodworking community to give her a little motivation to make stuff too. Visit these ladies and subscribe to their newsletters and YouTube channels!

- April at WilkerDos.com

- Cy at Cy's Corner

- Laura's YouTube Channel

- Sam at DIYHuntress.com

- Ana at Ana-White.com

- Linn at DarbinOrvar.com

- Sarah at Slowvannah.com

- Cristiana at Get Hands Dirty

The next time you are planning to make a project, think about making it a combo! It's a great way to turn a small area into a multi-functional space.

Sunday, July 17, 2016

I was on the CNC with Dave Show!

Thanks to Dave Gatton for inviting me to be the guest on his "CNC with Dave Show" on Saturday, July 16th. If you are interested in CNC machines, then you might want to tune into this show every Saturday night at 9pm on YouTube. I talked about the Electric Guitar that I made with the Inventables X-Carve and you can watch the playback below. Thanks to all who watched, joined us in the chat room, and asked questions. I had a great time!

Saturday, July 16, 2016

Make Some Easy Wall Shelves!

My daughter asked me to help her make some shelves for her room. Watch us have some fun in the shop while making these Easy Wall Shelves that anyone can make.

This is a great project for getting kids involved in woodworking. Going to the home center and picking out the wood is just as fun as making the project. Be sure to involve the kids in this initial step as well. Teach them look for defects and how to sight down a board to see if it is warped or twisted. It's easy to find examples of warped and twisted wood at the home center. Make sure you pick out good boards to avoid frustration during assembly.

You can easily make these shelves while teaching a kid how to use a hand saw or jigsaw. Or, you can do like I did and cut all of the pieces for them, then let them glue them together and paint them. Each child is different, so use common sense and good judgement to determine when they are ready to use dangerous tools. There are many other ways for kids to help in the shop.

I encourage you to involve kids in the design process as well, but if you would like to use our design, click here to download the free plan. We were able to make four shelves using one 1x10 and two 1x3's. Make sure you attach them securely to the wall by screwing into studs or wall anchors.

When working with kids in the shop, the most important thing is to have fun. You want them to have a good time. Tell jokes, talk about family history, talk about the future, listen to them, and laugh a lot. I know you will end up with a lot more than just a cool project out of the experience!

This is a great project for getting kids involved in woodworking. Going to the home center and picking out the wood is just as fun as making the project. Be sure to involve the kids in this initial step as well. Teach them look for defects and how to sight down a board to see if it is warped or twisted. It's easy to find examples of warped and twisted wood at the home center. Make sure you pick out good boards to avoid frustration during assembly.

You can easily make these shelves while teaching a kid how to use a hand saw or jigsaw. Or, you can do like I did and cut all of the pieces for them, then let them glue them together and paint them. Each child is different, so use common sense and good judgement to determine when they are ready to use dangerous tools. There are many other ways for kids to help in the shop.

I encourage you to involve kids in the design process as well, but if you would like to use our design, click here to download the free plan. We were able to make four shelves using one 1x10 and two 1x3's. Make sure you attach them securely to the wall by screwing into studs or wall anchors.

When working with kids in the shop, the most important thing is to have fun. You want them to have a good time. Tell jokes, talk about family history, talk about the future, listen to them, and laugh a lot. I know you will end up with a lot more than just a cool project out of the experience!

Monday, July 11, 2016

How to Make and Install Sliding Barn Doors

My neighbor asked me to build a pair of Sliding Barn Doors for his living room/office doorway. Check out my video below to see how I made them.

Supply List

These are the supplies I used to build and install the barn doors. The key to building these doors is lots of planning and measuring. You may need different supplies depending on the size and of your doors and how they will be installed, so adjust this list to fit your needs.

April Wilkerson of WilkerDos.com made some barn doors from plywood siding. This is a great alternative to rail and stile construction. I liked the way she used regular materials for the mounting hardware. Check out her video below and subscribe to her channel if you haven't yet. Thanks April!

Aaron at MrFixItDIY.com inspired me to use the rail and stile method to build these barn doors. Check out his video below and subscribe to his channel if you haven't yet. Thanks Aaron!

Supply List

These are the supplies I used to build and install the barn doors. The key to building these doors is lots of planning and measuring. You may need different supplies depending on the size and of your doors and how they will be installed, so adjust this list to fit your needs.

- 8-foot 2x6 boards (3 per door)

- 8-foot tongue and groove planks (6 per door)

- 8-foot 1x4 board (cut into 4 diagonal pieces, 2 per door)

- 8-foot 2x4 for mounting the track

- Wood glue

- 1 gallon of paint and paint brush

- 4 door handles

- 14-feet of steel flat bar, 3/16" thick and 2" wide

- 4 garage door pulleys with 3" diameter

- 8 bolts and 8 nylock nuts (for door hardware)

- 4 bolts, 8 washers, and 4 nylock nuts (for wheels)

- 8 lag screws 4" long

- 3 screws 1" long (for mounting track to 2x4)

- 2 felt pads to protect baseboards

Instructions

Here are some basic instructions for building and installing one barn door. Remember to make adjustments for your particular situation.

- Cut the 2x6 boards to length for the rails and stiles. Use a 3/4" dado set to cut 1" deep grooves into one side of all 2x6 pieces. The middle rail will need a groove on both sides.

- Cut tenons on both ends of the rails. Do a dry assembly of the door frame to measure for the panels.

- Cut the tongue and groove planks for the panels. To center the groove lines in the panel opening, you can rip the sides off one plank and use those pieces to start and end the pattern.

- Glue the three rails into one stile and let it dry.

- Slide the tongue and groove planks into place. The planks I used are plain one side and have a center bead on the other side, so make sure the boards are flipped the right way. Start and end with the thin spacer boards so the grooves are centered. I did not use glue between the planks.

- Glue the remaining stile to the other side of the rails.

- Once the glue is dry, sand and paint or stain the doors as desired.

- Cut four 15" pieces of flat bar. Drill a hole at one end for the wheel. Drill two holes at the other end for mounting to door. Sand any rough edges.

- Cut a piece of flat bar for the track. In my case, the wall space limited the track to 107" long. In general, the track will usually need to be about twice the width of the door(s).

- Paint the steel flat bar pieces and mounting hardware flat black.

- Mount the wheels to the top of the door using the 15" flat bar pieces. Make sure there is enough space between the top of the door and the bottom of the wheel to fit it onto the track.

- Cut the 2x4 board to the same length as the track. Mount the track to the 2x4 board using three screws, so that it overlaps the edge about 3/8" to allow clearance for the wheels to sit on the rail.

- Check above the door opening for a solid header or stud locations. Drill mounting holes through the track and 2x4 for the lag screws. Screw the track into place. Make sure it is sturdy because these doors are heavy.

- Hang the doors onto the rail. Make sure they clear door trim and baseboards and hang straight and square. You can make minor adjustments to crooked doors by slightly enlarging the wheel mounting holes and mounting the wheels a little higher or lower.

- Too keep a door from rolling off the end of the track, add an L bracket or strategically placed screw as a stop.

- If you do not want the doors to be able to swing out from the bottom, you can buy or make a bracket that will allow the doors to slide, but prevent them from swinging out.

- Attach the handles.

- Enjoy your new barn doors!

The supplies for this project cost about $200. If you purchased similar barn doors and hardware from a store and paid for the installation, you could expect to spend about $1,500 or more, so you can save a lot of money by making and installing them yourself. It took me about 25 hours of work over the course of 1 week to complete this project.

I am really pleased with out these barn doors turned out. It was a challenging project to build such large doors in my small shop, but they were a lot of fun to make. My wife has already requested that I make some for our home, so that means I get some more shop time! Yes!

Aaron at MrFixItDIY.com inspired me to use the rail and stile method to build these barn doors. Check out his video below and subscribe to his channel if you haven't yet. Thanks Aaron!

Wednesday, June 22, 2016

Harbor Freight Foot Switch Review

I recently bought a foot switch from Harbor Freight for my scroll saw. I thought it would be fun to try it out on other tools too. Check out my video then read more about my thoughts below.

Harbor Freight sells two types of foot switches. The Momentary Foot Switch (Item 96619) works like a sewing machine pedal - press it to make the machine run and release it to stop. The Power Maintained Foot Switch (Item 96618) works like a regular switch - step on it to turn on and step on it again to turn off.

I purchased the Momentary Foot Switch for my scroll saw, because it seems very similar to the use of a sewing machine. The switch works great for this purpose and I highly recommend it. I also recommend this switch for a drill press, sander, and even a router table where the router switch may be difficult to access. My only complaint is that it's made of plastic.

I don't see myself using a Momentary Foot Switch for larger tools, like the table saw, band saw, or lathe. I move around and change my stance a lot when using these tools, so keeping my foot on the pedal would be cumbersome. Also, the thought of accidentally shutting off power to a tool in mid-cut is kind of scary. The Power Maintained Foot Switch may be a better option for these larger tools. It could be useful as a secondary stop switch or for hands-free operation when handling large sheets of plywood, but I think the switch itself and the power cables could be a trip hazard.

There are some safety considerations when using foot switches, so make sure you follow the safety guidelines that come with the switch. If you have kids, pets, or frequent visitors in your shop, it's a good idea to turn off the tool's main switch when it's not in use and not rely solely on the foot switch. If you blow a fuse or trip a breaker, turn off the tool's main switch before resetting the breaker. Use common sense.

I can see where foot switches could make a production environment more efficient for repetitive tasks. For most of us in a home woodworking shop, speed isn't much of an issue, but there are still some good uses for them. Pick one up for about $13.99 (even less with a 20% off coupon) and try it out on a few tools to see what feels comfortable to you. Just make sure you buy the right type for your purpose.

Harbor Freight sells two types of foot switches. The Momentary Foot Switch (Item 96619) works like a sewing machine pedal - press it to make the machine run and release it to stop. The Power Maintained Foot Switch (Item 96618) works like a regular switch - step on it to turn on and step on it again to turn off.

I purchased the Momentary Foot Switch for my scroll saw, because it seems very similar to the use of a sewing machine. The switch works great for this purpose and I highly recommend it. I also recommend this switch for a drill press, sander, and even a router table where the router switch may be difficult to access. My only complaint is that it's made of plastic.

I don't see myself using a Momentary Foot Switch for larger tools, like the table saw, band saw, or lathe. I move around and change my stance a lot when using these tools, so keeping my foot on the pedal would be cumbersome. Also, the thought of accidentally shutting off power to a tool in mid-cut is kind of scary. The Power Maintained Foot Switch may be a better option for these larger tools. It could be useful as a secondary stop switch or for hands-free operation when handling large sheets of plywood, but I think the switch itself and the power cables could be a trip hazard.

There are some safety considerations when using foot switches, so make sure you follow the safety guidelines that come with the switch. If you have kids, pets, or frequent visitors in your shop, it's a good idea to turn off the tool's main switch when it's not in use and not rely solely on the foot switch. If you blow a fuse or trip a breaker, turn off the tool's main switch before resetting the breaker. Use common sense.

Friday, June 10, 2016

Sidebar Convo with Project Follow-Ups and a Shop Visitor!

In this Sidebar Convo, I follow up on some of my most recent projects. Also Keith Hurley from South Georgia visited the shop and I asked him a few questions about his brand new YouTube channel "Peccy's Place". Check out the video!

Show Notes:

- Subscribe to Keith's channel Peccy's Place.

- Make some simple Raised Garden Beds.

- Purchase my Scroll Saw Stand Plans.

- Watch my Scroll Saw Stand Video.

- Check out my Shoo Fly Don't Bother Me whirligig.

- See how I make Drumstick Pens from broke drumsticks.

- Have a look at my Sticker Spinner project.

Sunday, May 29, 2016

DIY Scroll Saw Stand for the DeWalt DW788

I designed and built this Scroll Saw Stand for my DeWalt DW788 scroll saw. Watch the video below to see how I made it, then continue reading for more info.

This scroll saw stand can be customized to fit other saws as well. Below are some of the features that I incorporated into the saw:

This scroll saw stand can be customized to fit other saws as well. Below are some of the features that I incorporated into the saw:

- Added casters so I can move it around and even take it outside on nice days.

- On-board storage allows for a place to keep scroll saw accessories and blades in the top bin, and the larger bin at the bottom can be used for cut-offs and scrap.

- The stand has a small footprint and is 25" tall, but can be customized with risers to make the saw tilt forward to reduce neck strain.

I have created a 20-page detailed set of plans for this project and made them available for purchase on my Etsy store. The plans included measured drawings, plywood layouts, actual size cutting templates, and detailed assembly diagrams and pictures. If you would like to build one of these stands, please consider purchasing the plans. Click here for the plans!

Thursday, May 12, 2016

Quick and Easy Raised Garden Beds

Make these quick and easy Raised Garden Beds in just one day! Watch my video showing the basic steps, then read further for a shopping list, step-by-step instructions, more photos, and a few awesome videos for extra inspiration!

Shopping List - Quantities shown will make one 48" square bed.

Step-By-Step Instructions

To make a square bed from 8-foot 2x6 boards, cut each board once at 49.5". This will also yield a shorter 46.5" piece. You should end up with four of each size.

Cut four 11" sections of 2x4 for the corners.

Stack two 46.5" board on top of two of the 2x4 pieces, making sure the 2x4's are flush and square on the ends. Drill pilot holes and screw them together - two screws at the end of each board. Repeat for the other 46.5" side.

Stand the two sides up so they are vertical. Stack two of the 49.5" boards on top, making sure the sides are flush and square with the ends of the longer sides. Screw them together. Carefully flip the partial assembly over and fasten the two remaining boards on the other side.

Cover the bottom with weed block landscaping fabric. Leave some excess around the bed if you will be landscaping around the beds. Use a stapler to fasten the fabric.

Flip the raised bed over and position it in place. Landscape around the beds if desired. Fill the bed with 15-16 cubic feet of your preferred garden soil. My wife selected Vigoro Organic Garden Soil and Miracle Gro Gardening Soil for Vegetables.

Plant your vegetables and don't forget to water them!

Make a sign to personalize your garden. I used an Inventables X-Carve CNC machine, but you can paint one just as easily. Be creative!

Below are some more awesome videos that may give you some other ideas for making raised garden beds. Enjoy and happy gardening!

Shopping List - Quantities shown will make one 48" square bed.

- Four 8-foot 2x6 boards, untreated

- A 4-foot section of 2x4, untreated

- 40 exterior screws (2.5" or 3")

- Landscape Fabric

- Stapler with 1/4" staples

- 15-16 cubic feet preferred soil

Step-By-Step Instructions

Cut four 11" sections of 2x4 for the corners.

Stack two 46.5" board on top of two of the 2x4 pieces, making sure the 2x4's are flush and square on the ends. Drill pilot holes and screw them together - two screws at the end of each board. Repeat for the other 46.5" side.

Stand the two sides up so they are vertical. Stack two of the 49.5" boards on top, making sure the sides are flush and square with the ends of the longer sides. Screw them together. Carefully flip the partial assembly over and fasten the two remaining boards on the other side.

Cover the bottom with weed block landscaping fabric. Leave some excess around the bed if you will be landscaping around the beds. Use a stapler to fasten the fabric.

Flip the raised bed over and position it in place. Landscape around the beds if desired. Fill the bed with 15-16 cubic feet of your preferred garden soil. My wife selected Vigoro Organic Garden Soil and Miracle Gro Gardening Soil for Vegetables.

Plant your vegetables and don't forget to water them!

Make a sign to personalize your garden. I used an Inventables X-Carve CNC machine, but you can paint one just as easily. Be creative!

Below are some more awesome videos that may give you some other ideas for making raised garden beds. Enjoy and happy gardening!

Tuesday, May 3, 2016

DeWalt DW788 Scroll Saw Unboxing and Bear Project

I've wanted to upgrade to a better scroll saw for a long time so I can make more detailed projects. Recently, the stars aligned and with the help of a store sale, some gift cards, and a little extra cash, I was able to order the DeWalt DW788 Scroll Saw. Watch as I unbox the saw and make my first project on it using Steve Good's Bear Cubs Silhouette Pattern.

The saw was packed well and arrived in new condition; however, I did encounter one minor electrical issue. The speed control dial was working intermittently. I noticed if I moved the plastic casing that it was attached to, it would affect the speed. I removed the screws and found that a wire connector was not properly seated. After fully plugging it in, the dial worked fine. This was really no big deal and an easy fix.

The saw was easy to assemble by attaching the table top with two bolts. That was it! It came with two blades so I could get started cutting right away. I am really happy with the performance of the saw and it is very easy to insert and remove the blade. I recommend finding a solution for holding up the arm temporary while you insert the blade into starter holes. I was blown away by how easy it was to make the detailed cuts in Steve Good's Bear Cubs Silhouette Pattern.

One of my buddies sells Scroll Saw Comfort Knobs that slip onto the standard DeWalt knobs and tighten with a set screw. The knobs come in small and large sizes. The large one slips on easily; however, the small knob requires that you sand the ends of the standard knob a little in order to get it to slip on. I highly recommend these knobs as they are much more comfortable to use than the standard knobs, especially if you have arthritis or other hand grip issues. For more information, email scrollsawcomfortknob@gmail.com. (Note: I understand that the Excalibur scroll saw knobs have the same threading, so you could add Comfort Knobs to your Excalibur if you order some of the DeWalt knobs too.)

If you are in the market for a scroll saw, I highly recommend the DeWalt DW788 Scroll Saw. I plan to make a stand for mine, but you might also want to consider getting the DeWalt DW7880 Scroll Saw Stand and DeWalt DW7881 Work Light. Stay dusty my friends!

The saw was packed well and arrived in new condition; however, I did encounter one minor electrical issue. The speed control dial was working intermittently. I noticed if I moved the plastic casing that it was attached to, it would affect the speed. I removed the screws and found that a wire connector was not properly seated. After fully plugging it in, the dial worked fine. This was really no big deal and an easy fix.

The saw was easy to assemble by attaching the table top with two bolts. That was it! It came with two blades so I could get started cutting right away. I am really happy with the performance of the saw and it is very easy to insert and remove the blade. I recommend finding a solution for holding up the arm temporary while you insert the blade into starter holes. I was blown away by how easy it was to make the detailed cuts in Steve Good's Bear Cubs Silhouette Pattern.

One of my buddies sells Scroll Saw Comfort Knobs that slip onto the standard DeWalt knobs and tighten with a set screw. The knobs come in small and large sizes. The large one slips on easily; however, the small knob requires that you sand the ends of the standard knob a little in order to get it to slip on. I highly recommend these knobs as they are much more comfortable to use than the standard knobs, especially if you have arthritis or other hand grip issues. For more information, email scrollsawcomfortknob@gmail.com. (Note: I understand that the Excalibur scroll saw knobs have the same threading, so you could add Comfort Knobs to your Excalibur if you order some of the DeWalt knobs too.)

Sunday, April 17, 2016

Shoo Fly Don't Bother Me Whirligig

I made a "Shoo Fly Don't Bother Me" whirligig for our local woodworking club's whirligig contest that was held at our Spring picnic. It was a beautiful day and the whirligig did a great job at keeping the flies away from my plate. Watch this video of the build and see it in action!

The propeller is made from fly swatters from the dollar store with the handles cut off. I made a red square hub out of wood and hot glued in the fly swatters.

I used leftover wire from a fly swatter handle, an eye bolt, and a piece of straight 1/8" steel rod to make the action mechanism. I cut these with large wire cutters and bent them into shape with pliers. This takes a little fiddling to get it to work smoothly.

I cut out the wooden parts, then drilled all of the holes prior to painting and assembly. I think outdoor whirligig projects look best with a mix of bright colors. I was really happy with the table cloth pattern I got by masking off stripes and spraying light coats. I attached a small wooden name badge on the whirligig.

Plus, the swinging hand keeps the flies away! If you've never tried to make a whirligig before, you should definitely try it. They are fun to make with a big payoff when the wind starts blowing. These are great projects for getting kids of all ages involved in woodworking. Have fun!

The propeller is made from fly swatters from the dollar store with the handles cut off. I made a red square hub out of wood and hot glued in the fly swatters.

I used leftover wire from a fly swatter handle, an eye bolt, and a piece of straight 1/8" steel rod to make the action mechanism. I cut these with large wire cutters and bent them into shape with pliers. This takes a little fiddling to get it to work smoothly.

I cut out the wooden parts, then drilled all of the holes prior to painting and assembly. I think outdoor whirligig projects look best with a mix of bright colors. I was really happy with the table cloth pattern I got by masking off stripes and spraying light coats. I attached a small wooden name badge on the whirligig.

Plus, the swinging hand keeps the flies away! If you've never tried to make a whirligig before, you should definitely try it. They are fun to make with a big payoff when the wind starts blowing. These are great projects for getting kids of all ages involved in woodworking. Have fun!

Monday, April 11, 2016

The Atlanta Woodworking Show 2016 Recap

The Woodworking Show in Atlanta was a blast! It was nice having the show in my home town. In this video I share some clips of the exhibitors, some selfies with other YouTube woodworkers, and pictures and video from about 25 people who visited my shop.

Here is a picture of the crowd at the Video Woodworkers booth. It was a pleasure meeting lots of other woodworkers and many people who watch my videos. If you missed the show, I hope you can make it to the next one where the Video Woodworkers booth appears.